The age of Computer Numeric Controlled Machines

Change is the only constant. Technology is one such facet of our creation that goes through constant upgrades. These technological advancements have made mechanics-controlled fields like Manufacturing processes much more feasible and efficient. One such machine in great use today is the CNC prototyping machine.

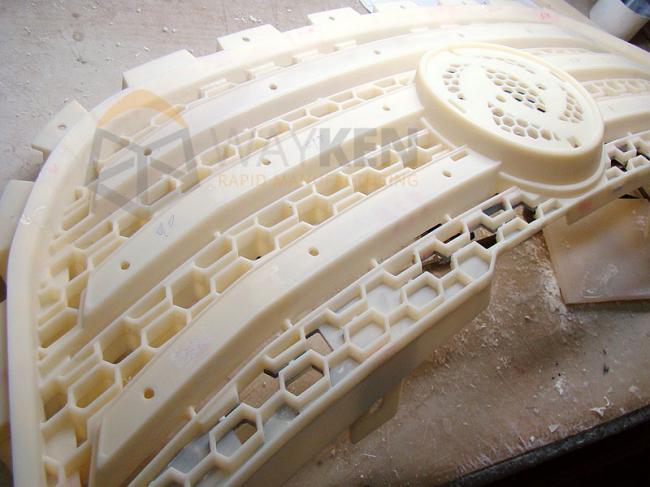

CNC refers to the process of cutting materials with a computer controlled numeric machines. The beauty of this machine lies in its simplicity. CNC machining prototype basically understands and explicates the generic 3D CAD model and interprets the data to the control machines. This allowed quality production grade materials can be manufactured.

So, let’s dive deeper into what CNC machining actually is..

The age of Computer Controlled Machines

The age of Computer Controlled Machines

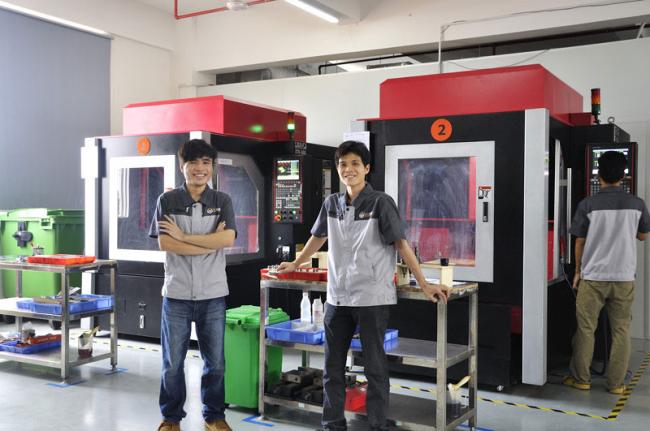

The first form of Numeric controlled machines was used in the 70s. This is when computers were introduced in the manufacturing domain and the term ‘Computer Controlled Machining Prototype’ was coined. In present day, the machine is found everywhere. From SMEs and business owners to Fortune 500 companies. The influence of this machine has been that beneficial!

The major advantage of using CNC machines is the production of industry grade materials, injection molds and fully functioning engineering prototype

Why is CNC so great?

The main idea here is to program every single action that an operator would have to take up with conventional machine tools. Mechanical process of drilling holes is an example.

Drill press is used to solder holes at the site of operation. We can place a drill in the drill chuck that is secured in the spindle of the drill press. Then, we can manually select the desired speed for rotation and activate the spindle. After which we manually pull on the quill lever to drive the drill into the workpiece being machined.

This drilling process was simple with the drill chuck and the spindle being used conventionally, but the drawback was that it required great human interventions. AT every turn, there was some action that called for humans to intervene. This did not prove efficient as in some manufacturing processes, skill of the operator is of high essence. It was evident, that more the human intervention required, more will be the chance of getting error ridden output. This is what CNC machines set to change.

Everything that an operator needs to do, can be programmed in a CNC machine. Once, the CNC machines are installed and running, the need for man-power at production site reduces drastically as most of the work is automated. Even menial tasks like test piece mounting on the system can be automated.

Here are some specific programable functions:

Motion control

Motion control

All CNC machines have this in common. They have two or more programmable directions of motion called – Axes. The number of axes contributes to the complexity of the system. Generally speaking, more the axes, more complex is the machine. CNC machines have more than 2 axes in real world environments.

The axes of CNC machines are essential for causing the motion needed for the manufacturing process. In the drilling example, two axes are used to position the tool over the machine and the third axes is used to machine the hole. Axes are named with letters. Common linear axis and common rotary axis are all named for convenience. They are generally assigned letters for indication.

The CNC Control part

The CNC control will interpret a CNC program and activate a series of commands in sequential order. Each command would require an appropriate machine function to be activated. It can cause a wide range of operations to occur. With high precisive calculations, these functions can yield better results.

CNC serves much more purposes than just interpreting the program. All current model CNC control allows self-testing and modification. Some other processes for verification and validation are also supported by the CNC program. In general, the CNC control allows all functions of the machine to be manipulated.

The Program behind CNC

The program or the code is the main driver of the ‘computer’ part of the machine. Think of it as giving a step-by-step instruction to the machine on the proper flow of task execution. A CNC program is nothing more than an instruction set. It's written in sentence-like format and the control will execute it in sequential order, step by step. For more controllability, a special series of CNC words are used to communicate what the machine is intended to do.

Applications of CNC

Applications of CNC

1. Metal Fabrication – One application of this machine consists of drilling precision holes in solid metal material used by the automobile, aerospace, construction, and other industries in producing end products..

2. Wood Manufacturing – Wood manufacturers also use this a of CNC machine as part of standard operations. In reality, a combination of CNC machines are used to perform all the manual tasks included in wood manufacturing like milling and grinding.

3. Computer Parts and Components Manufacturing – It is also common for manufacturers of computer parts and components to use a CNC machine for drilling. For this industry, precision is critical, which is what this machine offers.

4. Electrical Industry – Precision is the essence in manufacturing components and parts for systems. This is why CNC is a great fit here.

There is a huge shortage of skilled professionals who have adequate knowledge in operating these complex machines. With surge in demand, working with CNC can help you get job in multiple domains. With such high amount of usage, the application of this machinery extends beyond the realms of manufacturing processes. Computers now perform tasks that we as humans would find hard to do. It is evident that we are racing towards a world that will be ruled by technological advancements. People who ride this tech wave, which has been brewing for a while now, will be the frontrunners of their respective domains.

Support Our Journalism

We cannot do without you.. your contribution supports unbiased journalism

IBNS is not driven by any ism- not wokeism, not racism, not skewed secularism, not hyper right-wing or left liberal ideals, nor by any hardline religious beliefs or hyper nationalism. We want to serve you good old objective news, as they are. We do not judge or preach. We let people decide for themselves. We only try to present factual and well-sourced news.