Ventilators

Ventilators

Indian cos get licence to manufacture simpler NASA designed ventilators

Ventilators are in great demand during this pandemic period. The VITAL ventilators designed by NASA’s Jet Propulsion Laboratory for Covid-19 patients are affordable and simpler in design. Five Indian companies have recently received licences to manufacture it, reports Natasa Milas

We have all heard a lot about ventilators in the course of the coronavirus pandemic. Sadly, much of what we have heard has to do with the crises that can follow when ventilators are in short supply.

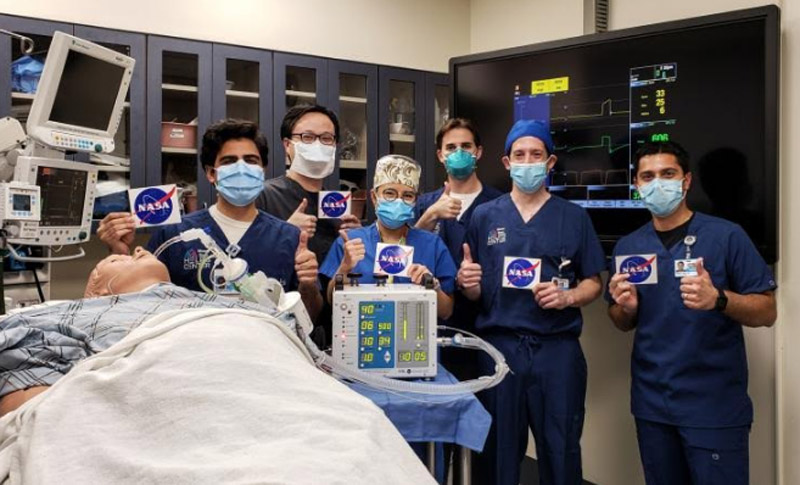

A team of engineers at NASA’s Jet Propulsion Laboratory (JPL) in California has designed a solution to help communities around the world affected by COVID-19. Ventilator Intervention Technology Accessible Locally, or VITAL, is a simplified version of a traditional ventilator used in hospitals and can be produced quickly and affordably.

VITAL ventilators use one-seventh of the parts of a traditional ventilator, and because of their flexible design, they can be used not only in hospitals but also in modified medical facilities like field hospitals set up in convention centres, hotels, and other high-capacity facilities across the world.

Like all ventilators, VITAL requires patients to be sedated and an oxygen tube inserted into their airway to breathe. VITAL will not replace current hospital ventilators, which can last years and are built to address a broader range of medical issues. Instead, VITAL is intended to last three to four months and is specifically tailored for COVID-19 patients.

VITAL was developed in just 37 days, with inputs from doctors and medical manufacturers, and has received ventilator Emergency Use Authorization (EUA) from the U.S. Food and Drug Administration. The authorisation allows for the use of the device specifically for COVID-19 patients to address the acute demand for ventilators during the pandemic.

“Our hope is to have this technology reach across the world and provide an additional source of solutions to deal with the ongoing COVID-19 crisis,” says Leon Alkalai, project manager of VITAL, manager of the Office of Strategic Partnerships and a JPL fellow. The design and production of VITAL ventilators is a collaborative project between the JPL team and companies around the world that were licensed to produce and implement them in the best possible way.

In India, five companies received licenses from NASA to manufacture VITAL ventilators: Alpha Design Technologies Pvt. Ltd, Bharat Forge Ltd, CuraSigna Systems Private Limited, Electrotherm Solar Limited and Medha Servo Drives Pvt. Ltd.

“India’s diverse nature means that the pandemic could affect the country in a variety of ways,” says Rashmi Shah, a research technologist at JPL, who was on the selection committee at NASA for the VITAL ventilator licenses in India.

“JPL’s approach was to develop the core device and, then, let local partners actually produce and support the product in the way that best supports the needs of the public. We assume that partners have the most in-depth knowledge of local laws and regulations and are best able to make sure that the ventilators are used where they are needed the most.”

While JPL has tremendous amounts of experience in creating and operating low-volume space systems, its foray into medical device development was a bit unorthodox.

“When the pandemic first hit the area around JPL, most of the lab’s employees were sent home. This period presented a unique opportunity for the lab’s scientists and engineers to do something completely different,” says Shah. “Since the perceived need was so great, we were quickly able to recruit medical partners who provided key insight into their needs and shared their specialized equipment that was needed to improve and validate our design.”

The JPL team quickly designed the simplified version of the traditional ventilators. A key challenge was to get a medical device like this approved by the U.S. Food and Drug Administration, which is usually a long process. “However, it has started issuing Emergency Use Authorizations for products that are to be used for the current pandemic,” says Shah. “These EUAs mean that critical products can be accepted for use in much less time than normal.”

NASA’s selection process when deciding which companies will receive licences to produce VITAL ventilators was very comprehensive. “We required interested companies to submit proposals indicating their capabilities and intentions,” says Shah.

“Essentially, we wanted companies that were able to manufacture quality products in a relatively short period of time.”

The selection criteria were proposed approach, experience, ability to scale production, servicing and product support. “We performed an initial filter on the proposals based on the above criteria,” says Shah, “and followed up with conference calls, performed background checks on the companies and employed other Internet-searching techniques to find out what we could about the companies. All this helped us evaluate and select the companies.”

VITAL ventilators in India are still in the prototyping phase and are yet to see full production and implementation. “We started this work relatively early in the pandemic, when the spread of the virus in India was very limited. We, and the companies that applied for licenses, saw a potential need and have proceeded on the assumption the virus might spread worldwide,” says Shah. “Since our partners are in the prototyping phase and have not begun full-scale production, these ventilators are not yet in widespread use in India.”

As of August 2020, 28 companies from 20 countries in the world received licenses to manufacture VITAL ventilators, including companies in India and the United States.

“Each licensee is working toward starting production as soon as they are able to,” says Shah. “While we cannot predict with certainty how COVID-19 will continue to affect the world’s population, should a purported ‘second wave’ appear, we hope that the VITAL ventilators produced around the world can save lives.”

Support Our Journalism

We cannot do without you.. your contribution supports unbiased journalism

IBNS is not driven by any ism- not wokeism, not racism, not skewed secularism, not hyper right-wing or left liberal ideals, nor by any hardline religious beliefs or hyper nationalism. We want to serve you good old objective news, as they are. We do not judge or preach. We let people decide for themselves. We only try to present factual and well-sourced news.